Part 3: Summary - Good, Bad & Scandalous

Bergey Turbine – the GOOD:

- Very simple design, with little to go wrong, wear out or break.

- Extremely strong blades. The 'pultruding' process means there is a very high quantity of orientated glass fibre which makes the blades exceptionally robust.

Bergey Turbine – the BAD:

- The blades are fixed profile along their whole length, which is

less than optimal regarding energy capture and noise.

- Old technology inverter makes an annoying whistle while operating.

- Poor design / manufacture leaves a number of components not

fitting or deteriorating in just a few months, for example:

- tail-fin cut from pre-galvanised sheet but has no post-guillotine treatment so cut edges rust,

- nose cone (spinner) doesn't fit properly so packed out with a stack of washers,

- nose cone anti-vibration mounts made from UV susceptible material and cracked badly.

- inverter display screws have no corrosion protection so go rusty.

- Cracks between blade and mounting saddle. In itself this is not of structural significance BUT it allows water/ice into the blade root which could not be inspected. Any problem at the blade root would be masked - a worry considering how often the turbine 'over-speeds'.

None of the above is particularly difficult to put right, but it demonstrates a poor design attitude or bad quality control.

Bergey Turbine – the SCANDALOUS:

The UK Government issued a certificate under its MCS programme and promoted and encouraged people to install this wind turbine. The certificate includes a noise specification, but despite being installed correctly (and checked by NAPIT) at certain speeds the Bergey doesn't meet its specification by a huge margin! Further, just above the test range the turbine is deliberately allowed to over-speed and make even more noise.I believe these faults make this turbine unusable near habitation and brings the whole Government certification scheme into disrepute.

- Cogging from the alternator induced resonance resulting in a 'fog

horn' noise, 'warbles' and acoustic disturbance significantly outside

its MCS noise specification. Listen to resonance recordings from

Part 2:

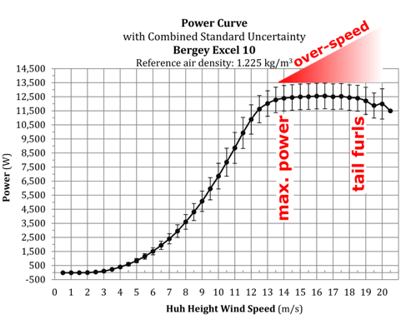

- Gross over-speed. Once the inverter reaches maximum power the

turbine stays into the wind with no mechanical regulation. The turbine

then escapes to a very high speed with associated massive noise output.

The noise has been compared to a helicopter or turbo-prop aircraft.

This is a deliberate Bergey design decision; I assumes it is in

order to maximise yield, which could otherwise make the Bergey appear

uneconomic.

- The turbine is not permitted to be left in a 'braked' condition, so can not be legitimately stopped after installation.

Hutchinson's Tower – the GOOD:

- Light weight with relatively small foundation block means minimal

environmental impact.

- Easy to build and fairly low cost.

Hutchinson's Tower – the BAD:

- Structural resonance when used with Bergey turbine.

- Excessive deflection (too flexible) during gusty wind conditions.

However my own (very crude) test using a Telehandler to support the tower

suggests that it does meet the deflection/load requirements specified

by Bergey in their 'Manufacturer Tower Design Requirements' document.

This suggests that the problem is more likely to be excess load being

applied by the turbine.

- Weld distortion of flanges leaves a question as to the exact tension in the fixing bolts.

Micro-generation Certification Scheme (MCS)

In the next part of this write-up I attempt to go through the correct procedure and raise a complaint via MCS. After a year this eventually results in a meeting with representatives from MCS, BRE Global (the certification company) and DECC ('Department of Energy and Climate Change'). In summary: they appear desperate to avoid recognising this as a scheme problem.The screen dump opposite is how MCS markets itself, be warned it is just propaganda.

- "MCS is a mark of quality ..." ?

Based on my experience that seems difficult to justify in the everyday sense of the word.

- "... and demonstrates compliance to industry standards" ?

Are standards written by the industry itself what consumers or the wider public need? I suggest we need protection from unscrupulous manufactures and false or misleading claims?

- "Consumer Protection" ?

I am £50,000 out-of-pocket and the only suggestion from MCS was "sue your installer". Where is the protection?

- "without miss-selling or misleading" ?

I purchased on the basis of the MCS certificate, but even its very restricted data isn't remotely accurate. With prima facie evidence of a problem, MCS itself is misleading consumers and the public as it continues to certify and promote this turbine.

- "satisfying rigorous and established European and International

standards" ?

Purchasers of renewable energy systems and those who are affected by them (all ordinary citizens) rely on the Government to ensure these standards are appropriate - THEY ARE NOT!

- "competence of installers" ?

Does that include SIAC / Bergey who nearly toppled my tower?